Power Punch Machines vs. Traditional Punching Tools

In the metal fabrication industry, punching is a critical process used to cut, shape, or form metal sheets. Over the years, advancements in technology have transformed punching methods, giving rise to power punch machines that offer greater precision, efficiency, and versatility. While traditional punching tools remain in use for some applications, understanding the differences between these two methods can help manufacturers choose the most suitable solution for their operations.

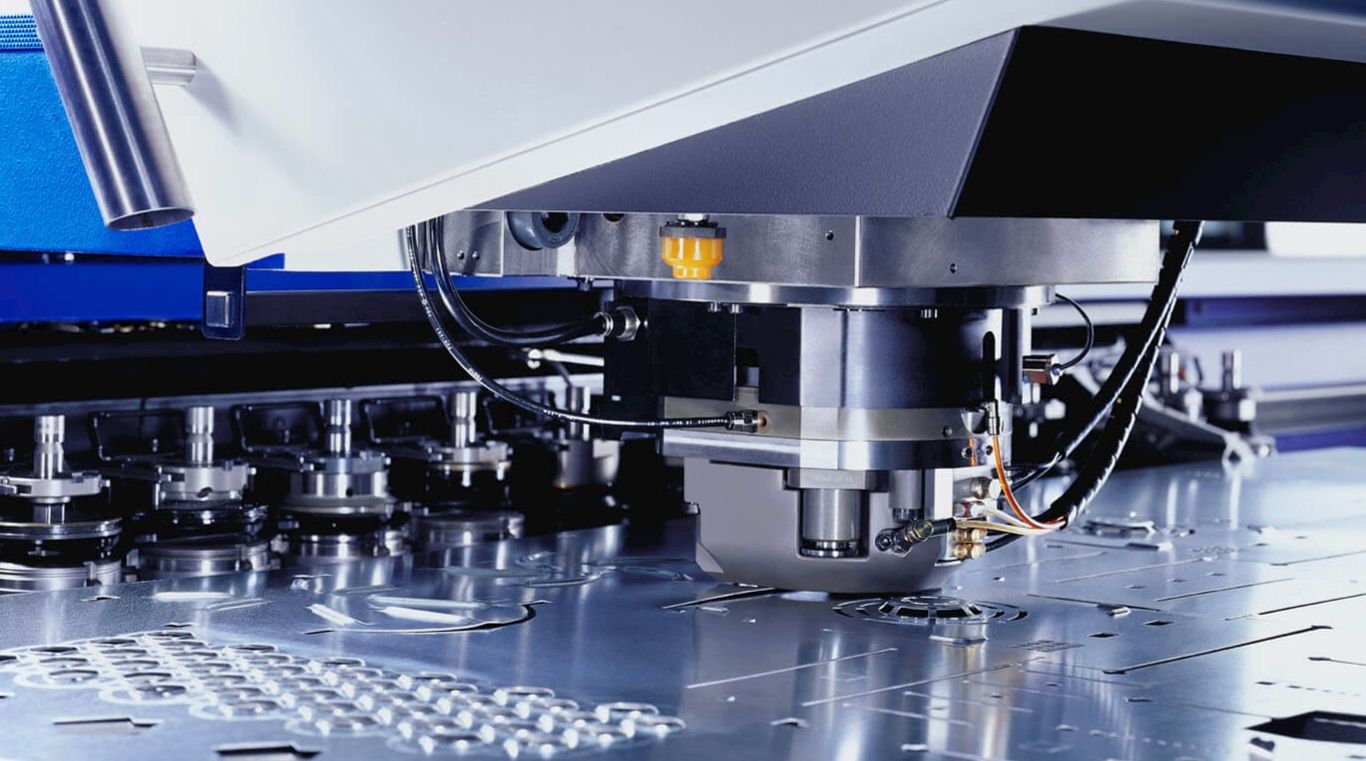

Understanding Power Punch Machines

A power punch machine is an automated or semi-automated device that uses mechanical, hydraulic, or servo-driven force to punch holes or shapes in metal sheets. Unlike traditional manual tools, these machines are designed to handle high-volume production with consistent accuracy and minimal operator intervention. Leading Power Punch Machine manufacturers integrate advanced control systems, automated feeders, and precision components to optimize performance and productivity. The result is a machine that can execute complex punching sequences quickly, reliably, and safely, making it ideal for industrial applications where precision and efficiency are critical.

Traditional Punching Tools

Traditional punching tools, often hand-operated or mechanically simple, rely on manual force or basic mechanical leverage to punch holes or shapes in metal. Examples include hand punches, arbor presses, and mechanical lever-operated punches. While these tools can be effective for small-scale or low-volume work, they are limited in terms of speed, accuracy, and consistency. The quality of the results often depends heavily on the operator’s skill and strength. Manual punching tools are generally more affordable and easier to set up, but they are not suitable for high-volume industrial operations where precision and repeatability are required.

Efficiency and Productivity

One of the main advantages of power punch machines over traditional punching tools is efficiency. Power punch machines can complete multiple punching operations in a fraction of the time required for manual methods. Automated material handling and programmable controls reduce downtime between operations, allowing continuous production of parts with minimal human intervention. In contrast, traditional punching tools require repetitive manual effort, which can slow down production and limit output. For large-scale manufacturing or industries with tight production deadlines, power punch machines offer a significant productivity advantage.

Precision and Consistency

Precision and consistency are crucial factors in metal fabrication, particularly in industries such as automotive, aerospace, and electronics. Power punch machines provide uniform results, with exact hole sizes, shapes, and spacing repeated consistently across all parts. CNC controls and advanced ram systems ensure minimal deviations, reducing material waste and the need for secondary finishing operations. Traditional punching tools, however, rely on the operator’s skill for accuracy, and minor misalignments or variations are common. While suitable for simple tasks, traditional tools cannot match the level of precision achieved by modern power punch machines.

Versatility and Automation

Power punch machines are highly versatile and can handle a wide range of materials, thicknesses, and hole shapes. Interchangeable dies and programmable sequences allow manufacturers to switch between tasks without extensive downtime. Many machines also integrate with robotic feeders and automated material handling systems, further enhancing efficiency. Traditional punching tools, by comparison, offer limited versatility. Changing dies or adjusting for different materials typically requires manual effort and time, making them less suitable for complex or high-volume applications.

Safety Considerations

Safety is another important factor where power punch machines have an advantage. Modern machines include protective guards, emergency stop mechanisms, light curtains, and sensors to reduce the risk of operator injury. Automated handling systems minimize direct contact with the punch and die during operation. Traditional punching tools, especially hand-operated versions, carry a higher risk of accidents due to close manual interaction, heavy leverage, and sharp edges. Operator fatigue can also increase the likelihood of errors and injuries.

Cost and Investment

Traditional punching tools generally have a lower upfront cost, making them attractive for small workshops or low-volume operations. They require minimal infrastructure and can be used with basic power sources or manual effort. Power punch machines, on the other hand, involve higher initial investment and may require additional space, power supply, and operator training. However, the long-term benefits, including higher productivity, reduced labor costs, and consistent quality, often outweigh the initial expense, particularly for industrial operations with high production demands.

Conclusion

While traditional punching tools still have their place in small-scale or low-volume operations, power punch machines clearly offer advantages in terms of efficiency, precision, versatility, and safety. By automating repetitive tasks and integrating advanced controls, these machines provide consistent results, reduce material waste, and improve overall productivity. Investing in a reliable Power Punch Machine ensures manufacturers can meet the demands of modern industrial operations while maintaining high-quality standards, making them a superior choice for most metal fabrication applications.