Common Issues Identified Using a Pipe Inspection Camera

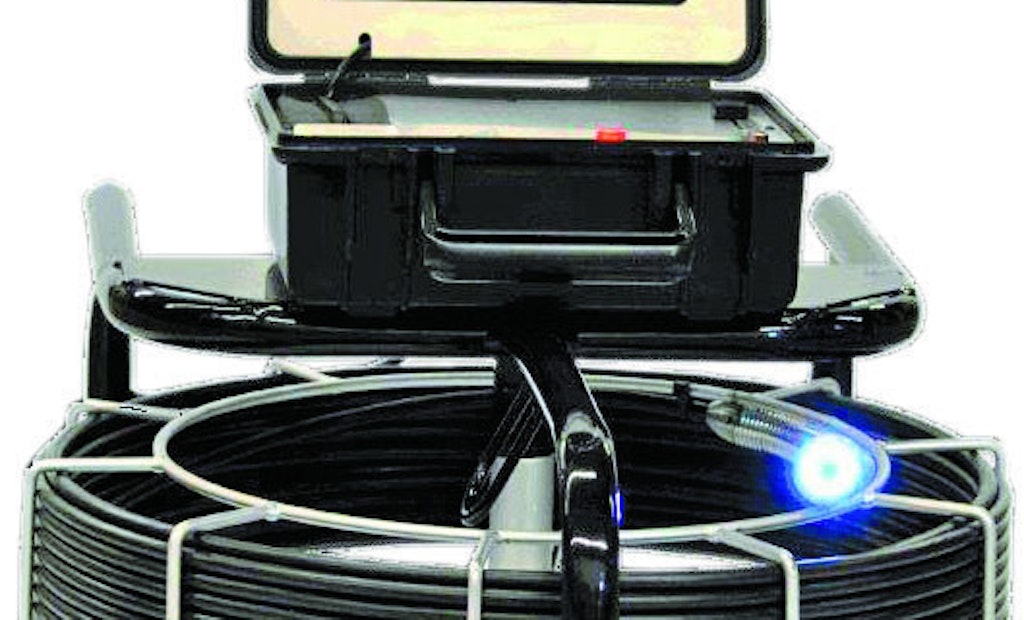

Pipe inspection cameras have revolutionized the way plumbing professionals, municipal operators, and industrial maintenance teams assess pipelines. By providing direct visual access to the interior of pipes, these cameras allow for accurate detection of blockages, leaks, and structural problems without extensive excavation. Understanding the common issues that can be identified using this technology helps operators perform targeted maintenance and reduce unnecessary costs.

Blockages and Obstructions

One of the most frequent issues detected by a Pipe Inspection Camera is blockages. These can be caused by a variety of factors including grease buildup, sediment, debris, or invasive tree roots. Blockages disrupt the normal flow of wastewater or liquids, leading to backups and potential property damage. With a pipe inspection camera, technicians can pinpoint the exact location and type of obstruction, enabling precise removal without unnecessary excavation or disruption.

Leaks and Pipe Breaches

Leaks are another critical problem often uncovered through camera inspections. Water loss, soil erosion, and structural compromise can result from even small leaks within residential, commercial, or municipal pipelines. High-resolution camera footage allows operators to detect the source of leaks, whether caused by cracks, corrosion, joint separation, or poor connections. Early identification using a pipe inspection camera reduces the risk of extensive damage and supports timely, targeted repairs.

Corrosion and Pipe Deterioration

Over time, pipes—especially those made from metal—can corrode due to chemical reactions with water, soil, or environmental factors. Corrosion can weaken the pipe wall, create holes, and eventually lead to leaks or pipe collapse. A pipe inspection camera provides detailed images of corroded areas, allowing maintenance teams to assess the severity and plan effective interventions. Detecting corrosion early helps prevent complete system failure and extends the life of the pipeline.

Structural Damage and Cracks

Structural issues, including cracks, joint displacement, and collapsed sections, are common problems in aging or poorly maintained pipelines. These defects can be caused by ground movement, heavy traffic, or construction activities near the pipeline. Using a pipe inspection camera, operators can identify these problems visually and assess their extent. This information is crucial for deciding whether localized repairs or full replacements are necessary.

Root Intrusion

In many sewer systems, tree roots pose a significant challenge. Roots can infiltrate joints or cracks, creating blockages and potentially widening the damage over time. A pipe inspection camera can reveal root intrusion at an early stage, enabling operators to remove roots before they cause extensive pipeline damage. Early intervention also helps in planning preventive measures to protect against recurring root growth.

Misalignment and Joint Issues

Pipe misalignment or separation of joints can result in reduced flow efficiency and potential leakage. Camera inspections reveal areas where pipes are not properly connected, helping technicians determine whether repairs, realignment, or joint sealing are required. Accurate identification of these issues ensures that corrective actions are targeted and effective.

Sediment Build-Up and Deposits

Sediment accumulation, often caused by mineral deposits, dirt, or sand, can gradually restrict pipeline flow. Over time, this can lead to decreased capacity, slow drainage, or pressure buildup. Pipe inspection cameras allow technicians to monitor sediment levels and determine if cleaning, flushing, or other preventive measures are needed to maintain optimal pipeline performance.

Documentation and Preventive Planning

Beyond immediate detection, pipe inspection cameras help in documenting pipeline conditions over time. By recording high-resolution footage of identified issues, operators can track deterioration patterns, recurring blockages, and areas prone to damage. This data supports preventive maintenance planning, reduces emergency repairs, and enhances long-term infrastructure management.

Conclusion: Leveraging Technology for Effective Pipeline Maintenance

Pipe inspection cameras provide an effective, non-invasive solution for identifying common pipeline issues. From blockages and leaks to corrosion, structural damage, and root intrusion, these cameras offer precise visual data that enables targeted maintenance. Using this technology allows plumbing and maintenance teams to plan repairs efficiently, reduce excavation costs, and ensure the long-term reliability of residential, commercial, and municipal pipelines. Integrating pipe inspection cameras into routine inspection programs is essential for accurate diagnostics, cost-effective maintenance, and proactive pipeline management.